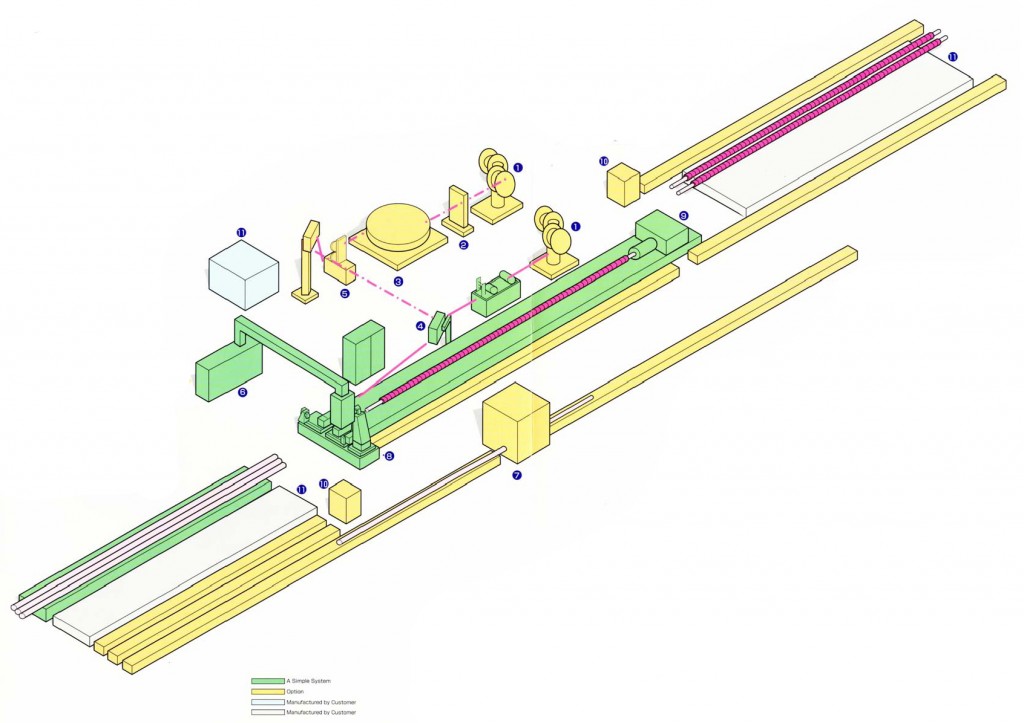

SPIRAL FIN TUBE WELDING MACHINE SYSTEM

This machine is capable of producing fin tubes, of various diameters, using a continuous finning process.

Finning requirements that may be performed by this system includes:

・Solid finning

・Serrated finning

・Spacing between fins

・Various heights of fin requirements

Finning requirements that may be performed by this system includes:

・Solid finning

・Serrated finning

・Spacing between fins

・Various heights of fin requirements

- Solid state welder can work out much higher welding efficiency and make it possible to reduce 30% of electricity consumption comparing with vacuum-tube type welder.

- The carriage uses AC servomotors enables to change fin pitches during welding.

- A horizontal fin accumulator saves spaces and maximizes work storage capacity.

- Touch Screen Control Panel which will display error messages, production data, power & speed of machine (by graph & digital values).

- The power is adjusted automatically according to rotation speed which allows for easy control by the operator.

- Easy access to the component of machines and equipment facilitates maintenance and minimizes repair cost.

- A shot-blaster (option) efficiently cleans and smooths tube surface for increased fin weldability.

- Flexible configurations make the system adaptable to any changes in the factory layout.

The Kusakabe Spiral Fin Tube Welding Machine System includes:

Solid Type

Serrate Type